|

Questions ? Call us at 905-624-5536. |

||||

|

|||||

|

DRO203 Digital Readouts

|

For International documentation: scroll to the bottom of our Manuals & Flyers page. |

|||||

| The most popular digital readout system in the machine tool marketplace, the DRO203 incorporates 7-inch color display technology with versatile software. Designed and manufactured in the USA, ACU-RITE readouts are the first choice of machine tool builders and users alike. |

Specifications |

|

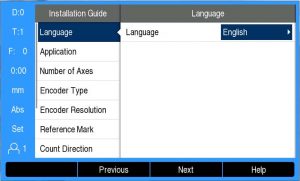

| Application | Milling, turning, grinding, boring and general purpose |

| Axes | 2 or 3 from A to Z and Z0 |

| Encoder Inputs | TTL |

| Display step |

|

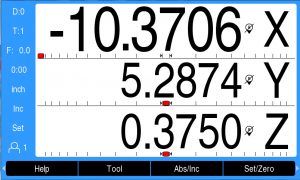

| Display |

|

| Status Display |

|

| Axis Display | Standard |

| Common Functions |

|

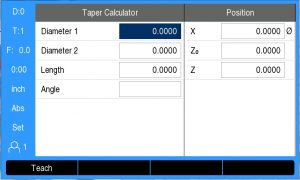

| Turning Specific Functions |

|

| Milling Specific Functions |

|

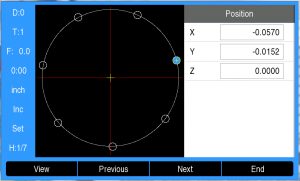

| Cycles | Oblique line, circular arcs; only for milling, drilling, boring:circular and linear hole patterns |

| Error Compensation |

|

| Data Interface | USB 2.0 type C

|

| Options |

|

| Electrical Requirements | AC 100 V to 240 V (±10 %), 50 Hz to 60 Hz (±5 %), = 33 W |

| Operating Temperature | 0° to 45º C (32º to 113º F) |

| Protection EN60529 | IP 40, Front Panel IP 54 |

| Weight | ~1.9 kg |