|

Questions ? Call us at 905-624-5536 |

||||

|

|||||

Cyclematic

CT-1118 Toolroom and gang CNC Lathe in one machine. |

with |

|

|

|

Switch from chucking or turning between centers to fast gang tooling work in minutes |

||

Convertible !

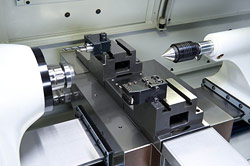

Now TWO lathes in ONE Centre turning and Gang Tooling SWAPABLE cross slide.  Center turning also gang turning on New CT-1118CNC CT-1118-CNC is the CNC version of CTL-618EVS manual toolroom lathe. It keeps the original machine's durability and elegant exterior while automating it with servos and CNC control. With CT-1118-CNC's redesign it maintains the ability to use the tailstock and center to perform shaft work. But now the cross slide can be removed and an innovative T-slot gang tool slide can be fitted, in minutes. The gang tool slide works with a new complete line-up of tool holders from CYCLEMATIC for gang tool turning. Either traditional lathe tooling setup or gang tool setup are easy to swap out and exchange for the other. Now CT-1118CNC is the ONE CNC toolroom lathe that can bring you TWO different styles of machining capability. |

Download the Cyclematic CNC lathe catalog updated to show the interchangeable cross slides for both lathe and mill series ) |

| This is the open version of the CT-1118. The spindle is a traditional Hardinge style with a 5C nose built in. We use a vector type spindle drive giving constant surface speed. Spindle speeds are up to 4,000 as standard and optionally to 6,000 rpm. The Anilam CNC is standard. Fanuc and others can also be supplied. | |

|

|

This is the same machine as shown above but with the 4 door chip guard system in place. A 3 door version is also available. |

|

|

|

| Shown without chip guards and with the Fanuc 0Ti CNC control |

Features: |

|

|

|

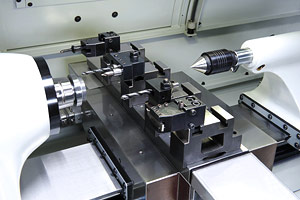

Bare cross slide with precision locator holes for custom applications |

Quick-change tool holder on "shorty" gang tool plate. |

|

|

Single tool on quick-change tool holder on compound tool slide.

Single tool holder in the back. |

Lathe canter in tailstock.

Single tool on quick-change tool holder on compound tool slide |

|

|

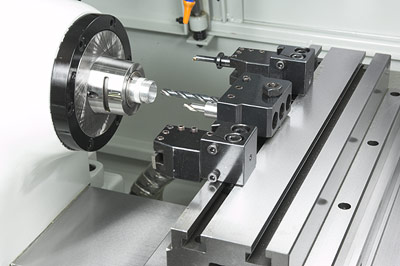

One full-length gang tool plate with T-slots to accommodate lots of tool holders |

Two "shorty" gang tool plates leaves room in the middle for long shaft work with the tailstock. |

MODEL |

CT-1118CNC |

| Maximum Swing | 280 mm 11" |

| Maximum Turning Diameter | Ø 150 mm Ø 6" |

| Distance Between Centers | 457 mm 18" |

| Bar stock Diameter (5C collet) | Ø27 mm Ø 1-1/16" |

| Hole Through Spindle | Ø31.75mm Ø 1-1/4" |

| CNC Controller | Anilam, Fanuc or Fagor |

| Spindle speeds (Variable) | 50~4000 R.P.M. (3HP) or optionally 50~6000 R.P.M. (5HP) |

| Spindle Nose I.D./O.D. | 5C 10° 4° external taper |

| Chuck Diameter | Ø150 mm Ø6" |

| Maximum X-axis Travel | 155 mm 6.1" |

| Maximum Z-axis Travel | 340 mm 13.4" |

| Rapid Traverse | 20 M/min 800 IPM |

| Inverter Spindle Motor | 3 HP optionally 5HP |

| X,Z-Axis Servo Motor | X : ß2 / Z : ß2 |

| Coolant Pump | 1/4 HP |

| Tailstock Spindle Taper | MT No.2 |

| Tailstock Spindle Travel | 95 mm 3.74" |

| Machine Dimensions (L x W x H) | 2050 x 1000 x 1650 mm 81" x 40" x 65" |

| Machine weight | 1200 kgs 2,640 lbs. |

MASSIVE SADDLE The saddle slideways are coated with Turcite-B for maximum wear resistance.The cross slideways have hardened and ground tool steel inserts for smooth accurate movement click to enlarge |

|

|

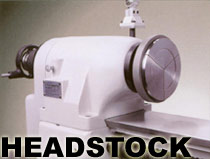

Solid one-piece enclosed headstock has high precision preloaded ball bearing spindle with 5C collet capacity. High-precision preloaded ball bearing spindle is mounted in the solid one-piece enclosed headstock, providing maximum rigidity and sustained precision. The collet seats directly in the hardened and precision ground spindle, eliminating troublesome sleeves and adaptors that introduce costly inaccuracies. |

|

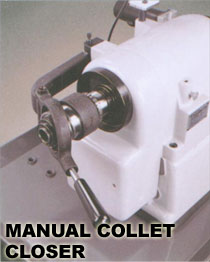

The fast lever collet closer provides faster chucking. The lever control end of the closer assembly is balanced and rides on a precision bearing. Collet tension is instantly adjustable throughout the full range from light to heavy holding power without the use of tools. The spindle handwheel is built into the end of the spindle. Entire collet closer is conveniently removed by pulling up the lock pin |

|

POWER COLLET CLOSER (OPTIONAL)

When requested, the lathe can be fitted with a easy type power collet closer to replace manual lever operation, this air operated collet closer features automatic chucking. |

|

The solid full bearing tailstock supports any load to the preloaded ball bearing spindle headstock, The tailstock has 95mm(3-3/4") travel. The spindle is graduated in inch and metric for easy reading. Standard shank 2 morse taper tools are automatically discharged for easy operation. |

|

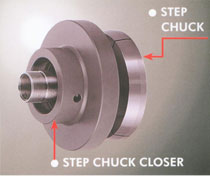

STEP CHUCKS are exceptionally useful for accurately holding work up to 6" in diameter. Castings, moldings, stampings and machined parts are held rigidly and accurately Tubing can be held without crushing or distorting. STEP CHUCKS AND CLOSERS are carried in stock in 2", 3", 4", 5" and 6" rated sizes. All step chucks are supplied with pin holes in place for precision machining. CHUCK CLOSERS fit directly to the machine spindle. A taper corresponding to that on the periphery of the step chuck places the closing pressure over the stepped area of the chuck, resulting in greater gripping power and accuracy. |

Expanding Collet |

Vacuum Chuck |

Hydraulic Chuck |

Chuck Back Plate |

6" 3-jaw Chuck |

|

|

|

|

|

Lathe Dog |

Face Plate |

Pneumatic Chuck |

Precision Diaphragm Chucks |

Step Chuck |

|

|

|

|

|

|

Tool Plate for Quick Change Toolpost |

ER Collet Holder |

Square Shank Tool Holder, Right Hand |

Gang Tool Block 408 mm |

Gang Tool Block 96 mm |

Gang Tool Block 48 mm |

|

|

|

|

|

|

Square Shank Tool Holder, Left Hand |

Square Shank Tool Holder, Right Hand |

Square Shank Tool Holder, 1 Position |

Drill Holder, Adjustable Center |

Releasing Die Nut Holder |

Tap Holder |